How To Hook Up Heat Exchanger To Water Heater

Introduction

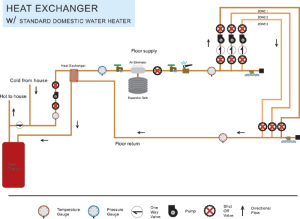

This system uses an efficient heat exchanger to carve up the potable domestic water supply from the flooring's anti-freeze mixture. Just ane heat source is used and the benefits of freeze protection tin exist fully utilized.

Oestrus substitution schematic with standard domestic water heater

However, ever ask yourself, "Do I actually need a heat exchanger?"

About often heat exchangers are used for freeze protection, but some other application would be a radiant arrangement with 1 heat source that, for one reason or another, must be separated from the domestic h2o supply. This is rare. Even the need for freeze protection is often overrated because a radiant arrangement stores so much rut in the mass of the habitation.

An example of a Radiant & baseboard / fan roll design.

A oestrus exchanger system using antifreeze tin protect the radiant heating system down to -60 below zero. But the tradeoff is efficiency. Transferring estrus from one medium to another (in this case, from beverage water to antifreeze via the oestrus exchanger) costs BTU'due south. The oestrus exchanger itself becomes warm and radiates into the surrounding air, though sometimes this heat helps warm a living space…even if that space is merely a utility room. Quite oft, the heat exchanger is insulated to minimize this effect. Nevertheless, any heat radiating from the heat exchanger is thermal energy that could accept gone to your floors.

In addition, antifreeze every bit a oestrus transfer medium is inferior to obviously water. Overall, a oestrus exchanger organization is 10 to 20% less efficient than an opensystem.

Of class, water has a nasty habit of freezing at temperatures below 32 degrees and in some situations this reality far outweighs the negatives of using a estrus exchanger. Heating a second home in a remote location prone to power outages would be a perfect profile for a heat exchanger system. In this scenario, you lot can drain the domestic water arrangement if you leave for weeks in the winter and the antifreeze protects the heating system.

Heating a remote edifice may exist another case. If you're sending water through a buried insulated pipage above the frost line, antifreeze is essential.

Solar collectors almost always utilize antifreeze, and so a heat exchanger is necessary in this application also.

The important betoken to understand is that most of the time estrus exchangers are not essential in a radiant organization.

EVERY heating unit of measurement that Radiant Floor company recommends and offers is "DESIGNED & RATED FOR Infinite HEATING"! These units are non your "typical" water heaters, so don't let the compact size fool you! All of our heating units are manufactured to an industry standard of quality and reliability.

These highly efficient heaters are built with Radiant heating in mind. We offer units that will heat both your Radiant (space heating) and domestic hot h2o.

Regardless of which radiant heating organization y'all choose, exist it Open, Airtight Or heat exchanger, or type of fuel source you lot crave, Propane, Natural gas, Electric or Oil,…Radiant Flooring company has y'all covered!!!

The Heat Exchanger Organization with a Tank-Type Water Heater

Heat exchanger packet with a Polaris h2o heater

The Polaris loftier efficiency water/infinite heater comes standard with 2 pairs of hot and cold entry and exit ports. This makes it ideal for use with a oestrus exchanger.

Using an On-Demand Water Heater with a Oestrus Exchanger System

With this pre-assembled rut exchanger plumbing package (photo above, schematic below), the on-demand water heater tin provide both space heating (using anti-freeze) and domestic hot (potable) h2o.

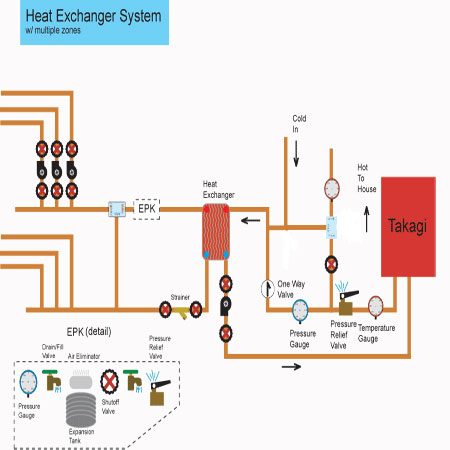

Heat Exchanger System with Multiple Zones

Cut a apartment plate heat exchanger in half and you lot'll find stacks of stainless steel plates. The two different fluids (normally water on one side, antifreeze on the other) menstruation betwixt alternating plates. The fluids themselves never mingle, but heat flows easily from the hotter to the cooler fluid.

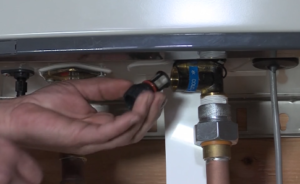

Mounting and Plumbing a Heat Exchanger

Oestrus exchanger mounted and plumbed

It is of import to plumb a heat exchanger in "counterflow" rather than in "parallel". Counterflow means that the hottest fluid entering Side A of the heat exchanger flows toward the coolest fluid inbound from Side B on the opposite cease of the oestrus exchanger (see illustration above). This maximizes heat transfer by forcing the coolest fluid to continuously flow toward the hottest part of the heat exchanger.

Plumbing in parallel would bring Side A "hot" and Side B "cold" into the same finish of the estrus exchanger and both would menstruation parallel downward the length of the oestrus exchanger. Of course, this inefficient plumbing configuration will still transfer some rut from the hotter to the cooler fluid, but a total 40% of the heat exchanger's capacity is lost.

Internal and External Estrus Exchangers

Sometimes a heat exchanger isn't a flat plate-type at all, but instead, is located Within a storage tank. Non surprisingly, these are chosen "internal heat exchangers". The advantages with the internal style are simplicity and efficiency. Elementary because only ane pump is needed to move the heat effectually, and efficient because although the external estrus exchanger transfers heat from 1 medium to another VERY chop-chop, information technology also radiates oestrus to the surrounding air.

Internal heat exchangers aren't as quick at transferring heat, but the heat has nowhere to get but to the surrounding h2o (which, ane might argue, besides leaks heat to the surrounding room — oh well, nil is 100% efficient).

So it really comes downwards to awarding, that is, which blazon of heat exchanger is best suited for a given heating system. Some systems utilize both types, as tin exist seen below.

This is a plumbing schematic we drew up for a client who wanted a wood boiler to heat a tank of h2o, which in plow provided both the home's domestic hot h2o AND the radiant floor oestrus. Oh, and the radiant floor had to contain anti-freeze, i.due east. it had to be "closed".

As y'all can see, this is a very complex heating organization. Most radiant systems are far simpler. But, equally an case of how vision can go reality, run into the photo below of the finished installation.

The storage tank with the internal heat exchanger is located across the frame of this photo, only it's function of this extraordinary example of do-it-yourself adroitness. Our client, Robin Ellins, proves that pride of ownership and attention to details, along with Radiant Floor Company's pre-assembled plumbing packages, tin effect in a heating system that rivals even the virtually elaborate professional installation.

Connecting the EPK to the Zone Manifold

The following cartoon outlines the copper fittings necessary to connect diverse sizes of Expansion and Purge Kits to the Zone Manifold. These fittings and a hard copy of this drawing are included with every Closed and Heat Exchanger arrangement.

Expansion and purge kits

FILLING & PURGING THE DOMESTIC (water heater) SIDE OF YOUR Oestrus EXCHANGER SYSTEM:

With a newly installed Radiant heating system, The first start upward is most crucial, purging air from your system is a must. Air in your system is the WORST thing that can happen to any (Hydronic) Radiant heating system. Follow this link, https://www.radiantcompany.com/system/opensystem/#Filling_the_Open_System For Open system filing and purging details too as On demand water heater filter cleaning / removing details. Plow off or disconnect the power supply from the water heater so that yous're not wasting hot h2o during this process.

Remember, but opening a domestic hot water fixture anywhere in the house will forcefulness h2o through the zone. Yet, opening the boiler bleed valve to the correct / above the mixing valve / thermometer is well-nigh convenient and offers all-time flow.

At that place'southward not a lot maintenance for our Radiant heating systems merely to make clean a filter in the water heater and maintain organization force per unit area. Follow this link, https://www.radiantcompany.com/details/fill/ and scroll down half the page for information on cleaning the filter & strainer for your Airtight Radiant heating system.

CLOSED (heating/zone) SYSTEM SIDE:

Filling and purging a Radiant heating arrangement is a disquisitional procedure! As air leaves a organisation the pressure will driblet. When your Radiant heating system heats upwards, the pressure will increment, but when it cools, it will drop in pressure….. Nosotros recommend that you maintain at to the lowest degree 15 psi when the system is cold. When a heated system's force per unit area is most 0,… and so cools,… it volition create a NEGATIVE pressure level… Thus creating a VACUUM, this will suck air into the system!

Your expansion tank is pre-charged and should not demand whatsoever pressure. If your pressure is dropping below the fifteen psi, information technology is an indication of air still trapped in your system,…. Air is the WORST affair that can happen to any (Hydronic) Radiant heating system. Follow this link, https://www.radiantcompany.com/details/fill/ for information on filling and purging your Closed Radiant heating system.

If you accept three zones, for case, close the brawl valves below the pumps for zones 2 and iii, and focus your h2o flow on Zone #1.

If Zone #one has multiple circuits of tubing, each circuit will have a brawl valve on the supply side of the loop manifold, close off all the circuits of Zone #1 except the showtime ane and channel the water into that get-go circuit. When circuit #1 of Zone #ane has been purged, then close off excursion #i and open circuit #2. Repeat this procedure for every circuit in every zone.

If you are not using firm pressure (from a hose etc.) then y'all may use a utility transfer pump, to pump the liquid into your organization.

We recommend Propylene Glycol (not automotive, Ethylene Glycol) antifreeze.

Determine how much antifreeze your organization requires by adding the total amount of fluid in the tubing (ii.7 gallons per 100 ft. of vii/eight″ Pex … 1.9 gallons per 100′ 3/4″ pex… 1.three gallons per 100ft of 1/ii″ Pex) plus the book of h2o in the Oestrus source (water heater or banality).

Determine what percent of anti-freeze to water mixture is recommended by the manufacture of the heat source. Ratios tin can vary. Some manufacturers recommend anywhere from 20%, 30 % anti-freeze, other's l%. The proper mix is as well influenced by the degree of low temperature you wish to protect against. Some antifreeze comes "Pre-diluted" Be sure to check before purchasing.

"Always PRE-MIX YOUR ANTIFREEZE Before PUMPING IT INTO YOUR SYSTEM"!

A utility transfer pump — NOT a sump pump is to be used when back flushing a unit and when filling and purging a Closed system utilizing an antifreeze mixture. We recommend a powerful utility pump like the Wayne EC-50, or the Wayne PC-4,or an equivalent pump like the Utilitech .5 HP Cast Iron Transfer Pump, all of which tin generate up to 45-psi. The following link https://www.waynepumps.com/solution-middle/utility-pumps-transfer/pc4 are specifications for pump (Model # PC4).

How To Hook Up Heat Exchanger To Water Heater,

Source: https://www.radiantcompany.com/system/the-heat-exchanger-system/

Posted by: kelleynobster.blogspot.com

0 Response to "How To Hook Up Heat Exchanger To Water Heater"

Post a Comment